All files for this project are available on thingiverse.

After a lengthy tour of the Oregon coast last summer on my homemade recumbent – it was clear the shifter’s mount could stand some improvement. So – I went ahead and did a full redesign.

A decade after the original – I’ve decided to update my 3d-printed friction shifter design (old version here).

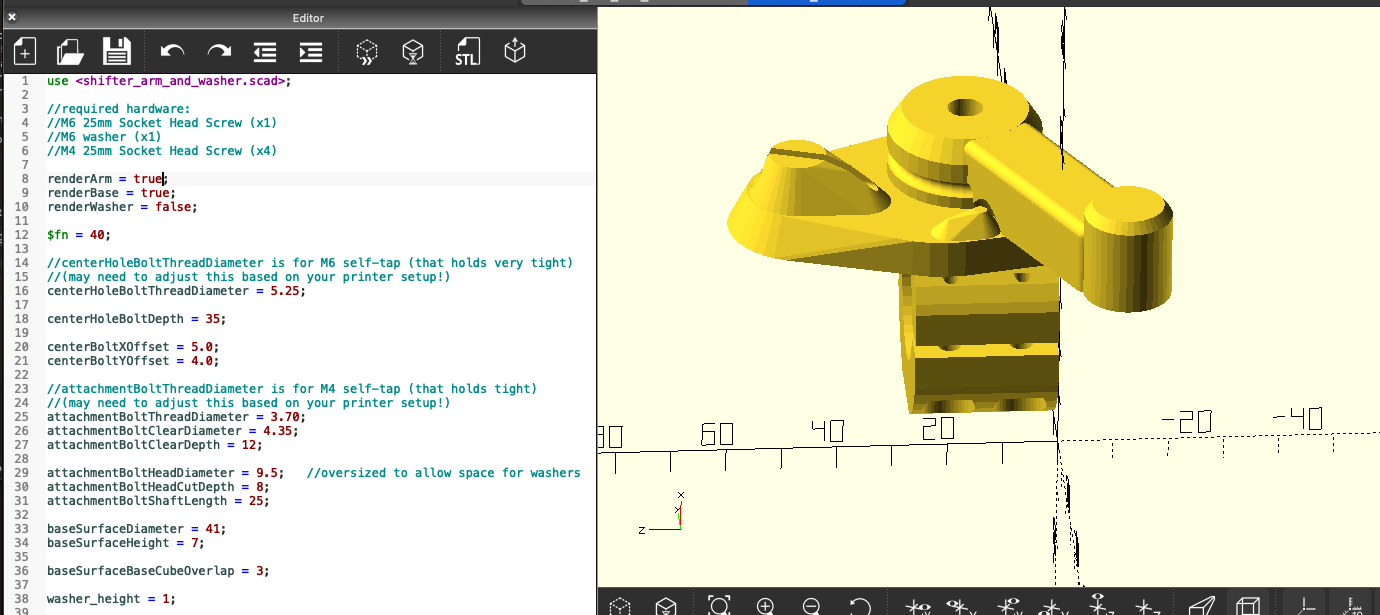

First off – the new version is designed in OpenSCAD for easy modification (old version was SolidWorks).

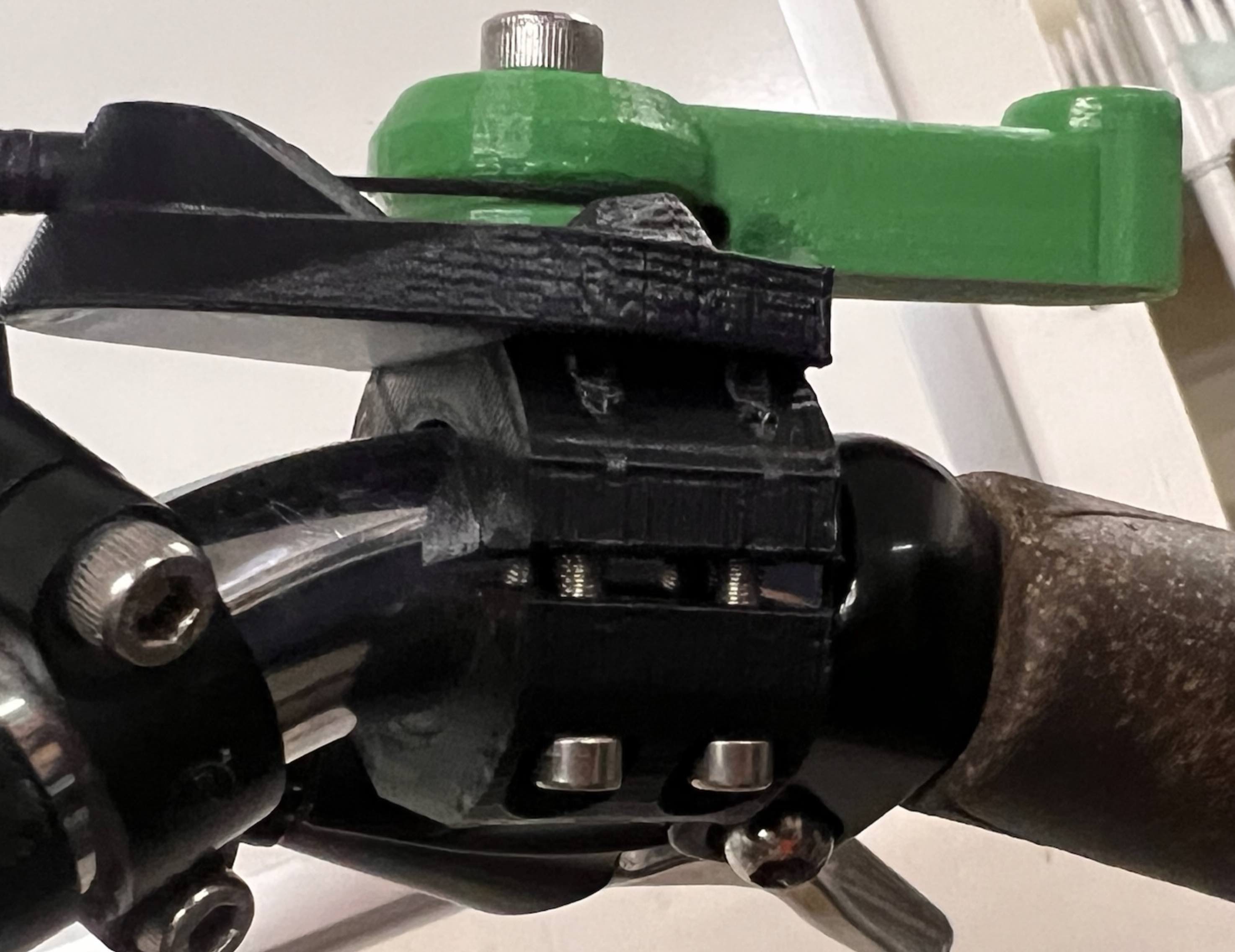

The mount now clamps tightly to a standard 22.2mm handlebar without tape. You can easily change dimensions if needed. All holes are self-tapping. I have not had problems with the screws backing out.

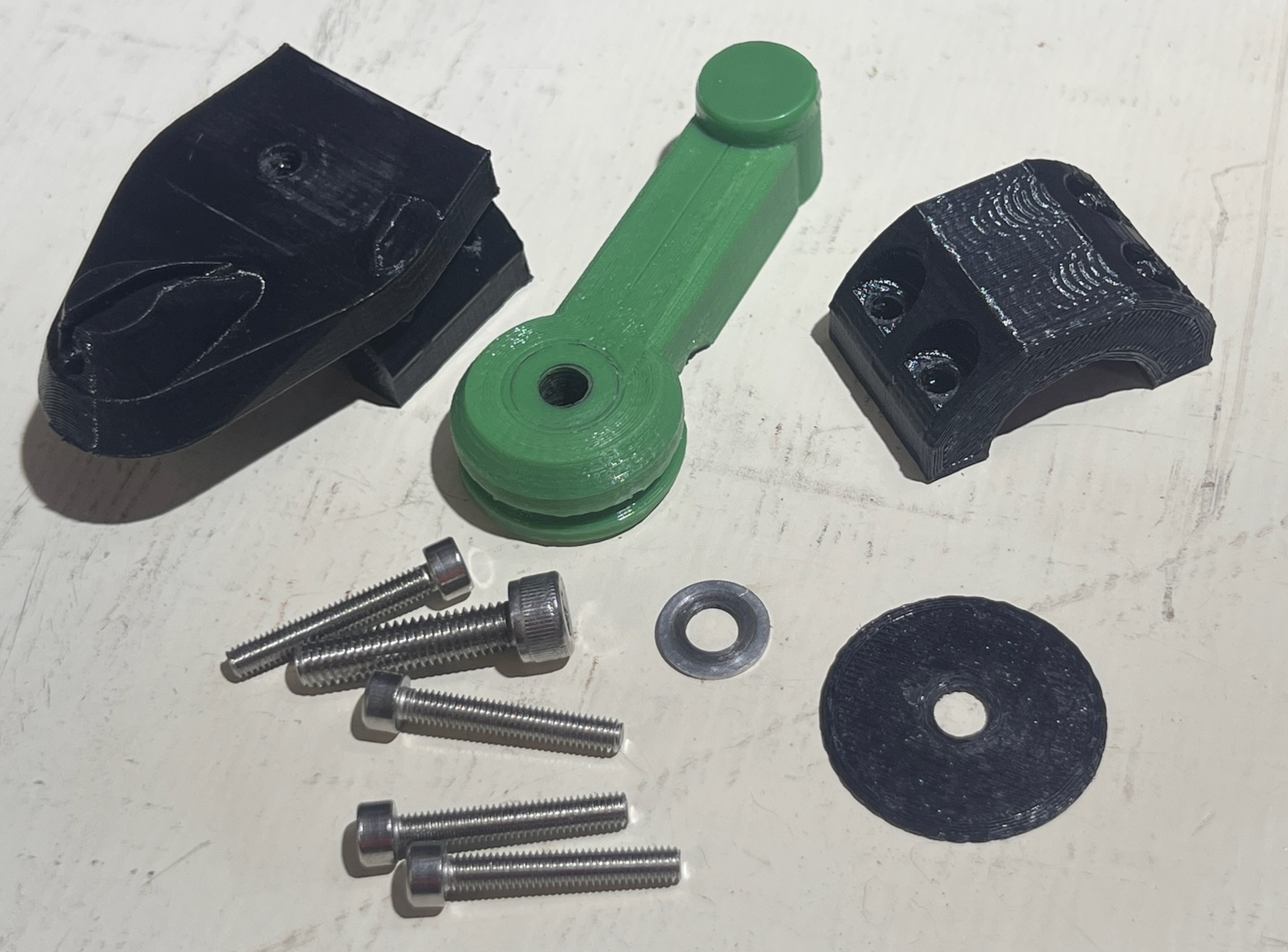

Additional parts required:

1x M6 25mm Socket Head Screw

1x M6 Washer

4x M4 25mm Socket Head Screws

Print with 4 or more shells for good strength.

I’ve had the best luck with standard PLA for the base. If you have issues with the print delaminating when threading the screws – try printing hotter / reducing the cooling fan.

(I did not have good luck printing in 20% Carbon Fiber PLA – tended to delaminate).

The lever can be printed with a harder flexible filament (Shore 95a or harder). This makes for a nice feel. If going this route – I recommend printing as close to solid as possible (ie – 10x shells / 75+% infill). For the lever in this print I used “Overture TPU” filament.

I am using it with a Shimano XT-R 10-speed setup. There is plenty of additional cable pull capacity. I suspect it will work with any derailleur setup currently on the market.

Slicers / printers etc. may effect holes sizes. If things don’t cooperate – tweak the OpenSCAD files as needed. If you encounter issues with threading – you could always thread the holes manually with a tap.

Again – all files for this project are available on thingiverse.

One thought on “3D Printed Bike Shifter (2023 Update)”